Engineering

Several refineries of site-one of South Pars Gas Complex (SPGC) use the wet gas of 4th refinery (Phases 6, 7 & 8 of South Pars Gas Complex) to compensate lack of their feed gas from offshore. Development of BUSHEHR Petrochemical plant in near future will demand more ethane feed from the 4th refinery. This will cause not to be able to send the wet gas to other refineries of site-one as before, hence feasibility of sending sour dry gas from export gas of 4th refinery should be studies.

The wet gas of 4th refinery after dehydration, ethane recovery and LPG recovery is pressurized via export gas compressors (Unit 106), to be exported to the IGAT5. The pressure and temperature of this dry gas at battery limit of 4th refinery is varying between 80-90 barg and 31-55oC respectively. The pressure of IGAT5 changes due to dry sour gas demand and its temperature changes due to seasonal change of ambient air.

Therefore, in order to replace wet sour gas with sour dry gas as feed of other refineries of site-one following should be evaluated:

- Effects of pressure increase with respects to control and safety of receptive refineries and feasible solutions.

- Effects of temperature increase on Gas Sweetening and Ethane Recovery Units in receptive refineries and feasible solutions.

- Mission:To do brownfield engineering project regarding commissioning, start-up and operation of:

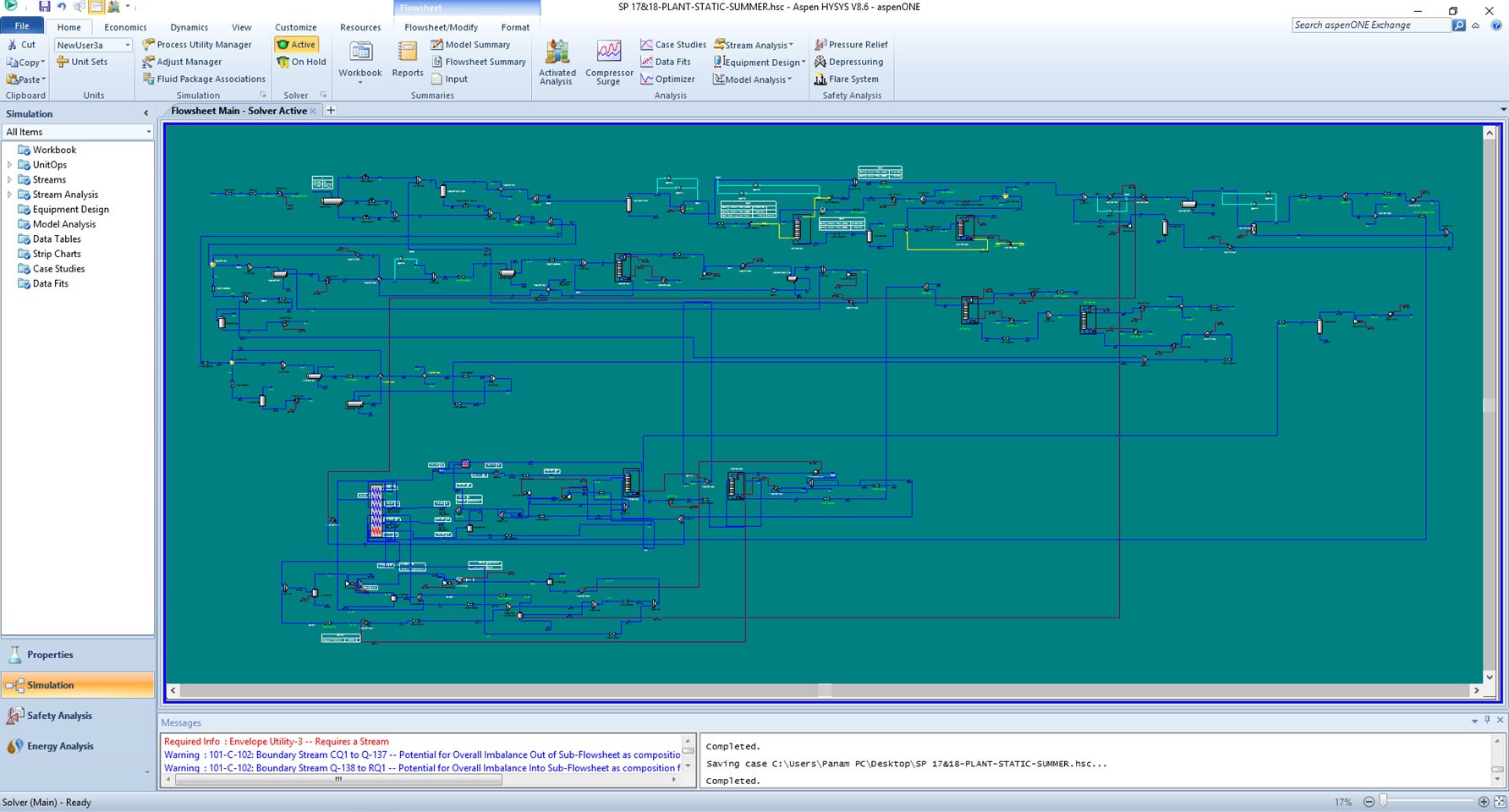

- South Pars Gas Field Development Phases 17&18

- South Pars Gas Field Development Phases 20&21

- Bandar Abbas Gas Condensate Refinery

- Client:Oil Industries’ Commissioning and Operation Company (OICO)

- Start Date:Sep-2016

- End Date:Live

- Project Value:1.6 Million USD